|

|

|

|

|

|

| Control Jacquard by USB Devices (Memory Drive, Floppy Drive etc.) |

|

Select Jacquard Needle directly with USB Devices (Memory Drive, Floppy Drive etc.) which made by Design System.

It is unnecessary to make up Punching Card for Mechanical Jacquard. Be able to begin weaving immediately if there is Jacquard Data.

It is the operatable to exchange Mechanical Jacquard for Our Products.

|

|

Raschel Lace Design System:SUPER-LECS 3

Over 30 years of experience with multi-window capabilities via XWindow...

Highly effective presentations

Accelerated pattern breakdown process

Pattern check before manufacturing

A product that covers everything, including the transfer of know-how.

|

|

|

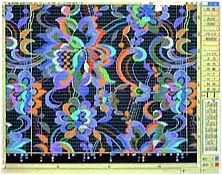

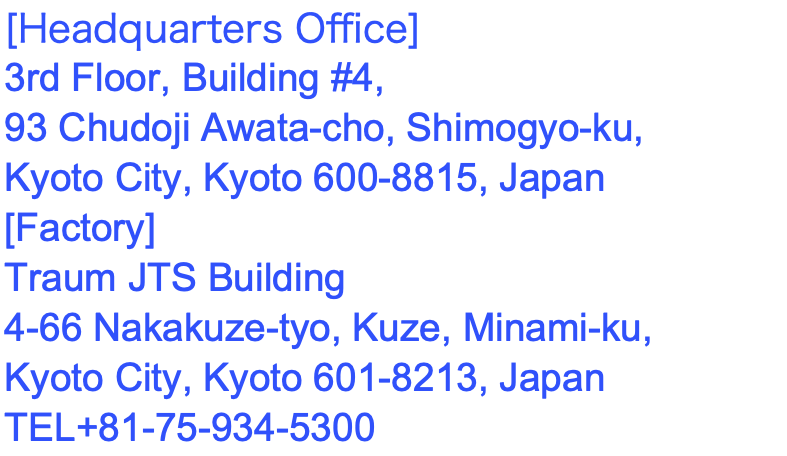

|  Original Image Input Original Image Input

・Scanning and displaying sketch originals clearly

on the monitor.

Using a responsive pen-touch digitizer,

edit the original image freely with a rich color palette

and drawing functions.

Liner/Yarn Input Liner/Yarn Input

・Automatically input liners/yarns based on

the color-edited original image.

Yarn diagrams are instantly generated

from the original image.

・Display chain/tulle structures in a grid according

to various densities.

This function is essential

for precise design adjustments.

・ The yarn display settings can accommodate various

design types, including differences in thickness

and loop yarn representation.

・Enhanced editing functions include yarn flipping,

copying, replacing, repeating, inserting

and merging different designs, and connecting them.

|

|

Ground Input Ground Input

・Minimized tedious manual input by repeating database ground patterns in color-coded areas

and tracing pattern yarns onto the ground.

|

|

|

Machine data Machine data

・Can convert to punch card data and output to floppy disk, as well as

output various electronic control data.

Printing Printing

・Print output of chain lists based on drawing data.

・In addition to printing out preparation and setup information for each knitting machine, checks

such as yarn breakage, maximum swing width, collisions of shuttles, maximum chain value, etc.,

are performed and printed out as lists.

・Furthermore, output documents useful for process management and cost calculation,

such as registering yarn material and numbers, and calculating yarn usage from drawing data.

|

|

|

Integration with SKY-HR/V Integration with SKY-HR/V

・Designs created with SKY-HR/V can be imported into SUPER-LECS 3.

Integration with ELFIN-REAL Integration with ELFIN-REAL

・Data created with SUPER-LECS 3 can be called up from ELFIN-REAL to perform detailed Raschel lace simulations.

|

|

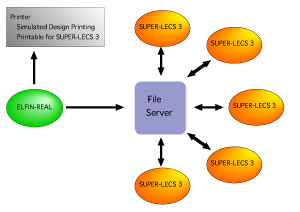

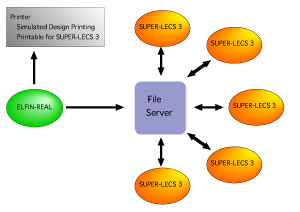

|  Integration with Multiple Devices Integration with Multiple Devices

・By managing data on a file server, data exchange

between systems is possible without the need

for media transfer.

It is efficient as operators do not need to move.

・When reading data from ELFIN-REAL, folders are set up

for each SUPER-LECS 3, allowing for precise

searching of the designs to be simulated.

・You can set the types of yarn, thickness, and color

uniformity for each type of yarn in ELFIN-REAL.

Data created in individual systems can be simulated

under the same conditions, improving work efficiency.

・Plotter for Drawing Printing,

Printer for drawings, chain tables, and simulation

printing, Remote printing from each system is possible

even with only the two printers mentioned above.

This remote printing saves on capital investment.

|

|

|

|

|

Updated Date:2024-06-19-(Wed)T19:47:24

Format version:5.00